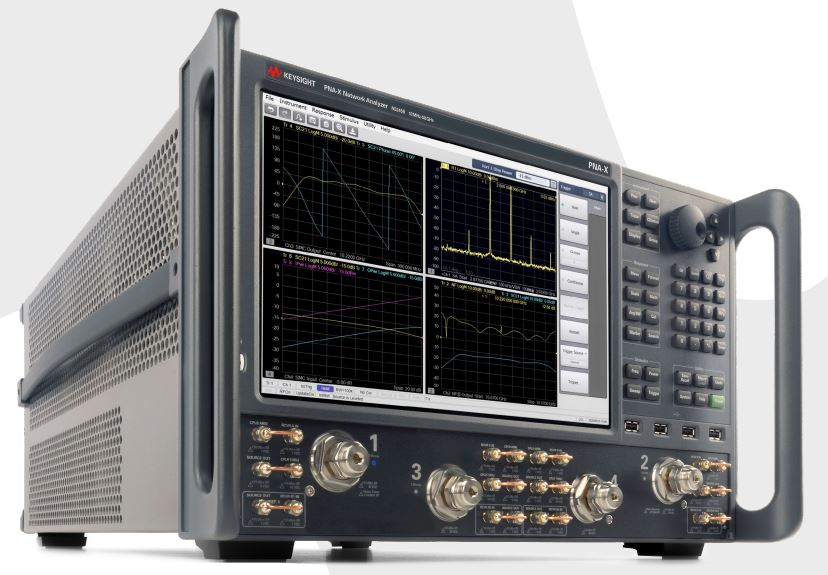

RF Devices require stable and repeatable test and measurement solutions to ensure constant product quality. Wireless systems require many RF and microwave components from passives, data converters, filters, mixers, amplifiers to antennas.

Characterizing these devices in small lots and verifying in mass-production require flexible and fast test and measurement solutions which support basic RF measurements all the way to standard-compliant modulation schemes.

RF Future provides leading-edge solutions for component test for on-wafer to final packaged devices, from streamlined RF test to complex protocol scenarios for production and characterization for multiple applications and technologies.

Our solutions to Your challenges

Characterization and production have many things in common. Actually, production testing is often derived from the characterization procedures and methods with reduced test depth.

- Ensuring product quality while scaling from lab samples to mass deployment

- Automated testing with the right balance of test accuracy and speed

- Faster to market with fully qualified products

- Correlation of test results from development through characterization to production

Specific requirements in characterization:

- Characterize the lot within a short time while maintaining a high level of accuracy and sensitivity

- Verify the components in a small lot across corner cases in level and temperature to release for production

- Run stress testing, also called highly accelerated stress screening (HASS) and highly accelerated life cycle testing (HALT) to ensure product quality

Specific requirements in production:

- Enable highest throughput using speed optimized testing and minimized test depth

- Ensure only good devices will leave the factory using the right amount of testing

- Find faulty units as early as possible in the production process