Who we are:

We are a diverse group of battlefield-tested engineers and leaders in various fields of semiconductor/ RF industry. Our team members have decades of in-depth knowledge, skills, expertise, and experience in the real-world environment on various RF products for various applications on various technologies. Our dedicated and motivated engineers are professionals and industry experts who modeled and designed numerous state-of-the-art designs, characterized, debugged, performed FA and reliability tests, and followed the entire process to put products in production. Working as both (customer and vendor) at various stages of our professional career.

What we will do for you:

We clearly understand and realize needs, urgency, requirements, and expectations for optimal performance, quality, reliability, and time-to-market of products (with all levels of integration and complexity) while minimizing the overall cost.

Through our decades of experience, we bear the capacity and capability to not only model, design, debug, and test optimum products but also foresee potential problems and issues, and area for optimization of existing products and/or designs. Our rewarded executions and support to the most challenging and demanding customers on the most technologically advanced products in the semiconductor/ RF markets can and will make a significant difference to your company.

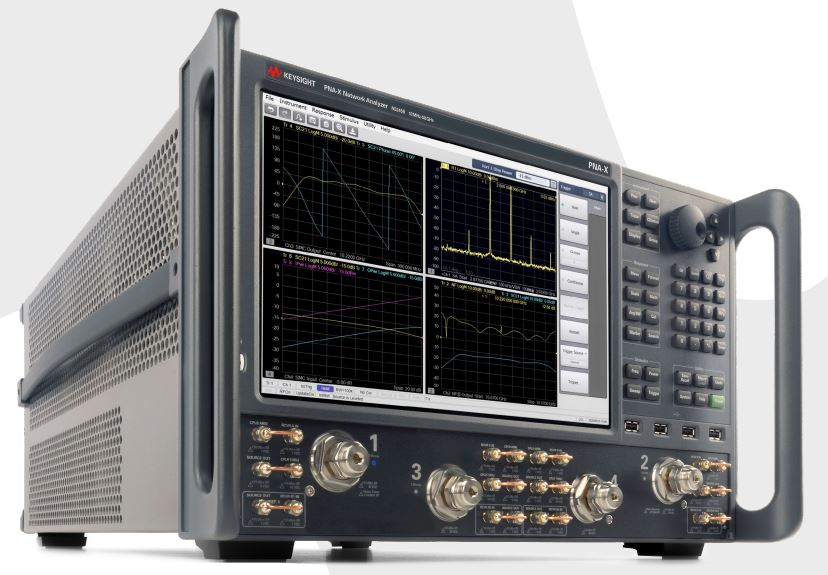

We are directly engaged and involved in future generations of modeling, design, debugging, characterization/testing, and validating products/ tools in the lab and production environment. We have years of experience and knowledge in quality and reliability requirements and tests.

From the early stage of the concept, modeling, probe/ test of a die, substrate, passive BOM components, package and compounding parasitic effect to final system-in-package and test circuits/boards, we progress with a mindset of a product that not only has high performance, but also can be mass produced with higher yield, higher quality, reliable, lower cost, and quick time-to-market.

In the production environment, we will utilize in-depth skills, knowledge, and experience in ATE (Advantest, Teradyne/ LitePoint, Cohu, etc.), handlers, and daughter cards/load boards. We have years of experience in statistical data analysis of a large amount of production data using various statistical tools, multisite conversion, test time optimization, yield improvement, etc. Our HVM process includes golden samples selection, Bench2Bench, Bench2ATE, ATE2ATE, SITE2SITE correlations, and GR&R activities on Characterization Lab fixtures and production load-boards. Our service includes taking the whole project from the concept phase to production or any segment that you need help with. We are flexible to travel to your site or deliver the solution. Consider us as one of your employees, but without having to provide company employee benefits.

Let’s get to work!